Basic process of refining is same in both batch & continuous refinery. Only difference is instead of a measured batch, crude oil is processed continuously with constant stream of flow. In between required utilities & chemicals are added continuously in measured quantity. Crude oil from obtained from expellers, solvent extraction plant contains foreign impurities such as mucilage, gums and unfiltered proteinous matter from the seed. It also contains gums which making it unfit for edible

purpose. Basic stages of the process are as below:

- Nutralizing

- Bleaching

- Dewaxing & Deodorizing.

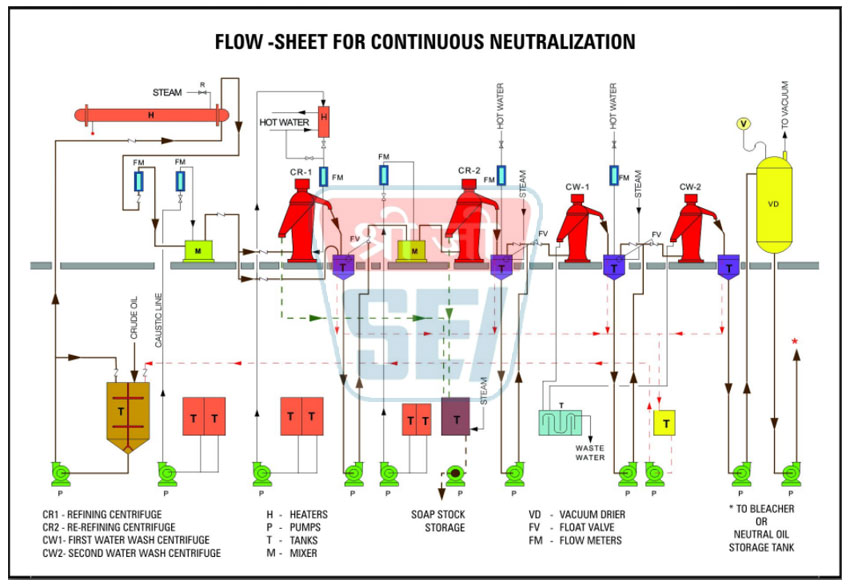

DEGUMMING AND NEUTRALIZATION SECTION

- The crude oil is pumped to Neutraliser from oil mill or storage tank & first it is treated with weak solution of phosphoric acid or other suitable degumming agent for removing gums.

- Thereafter oil is further treated with measured quantity of alkali (NaoH) depending upon free fatty acid (F.F.A.) in crude oil. In this process soap will be separated.

- Next process is hot water wash to the oil to remove traces of soap particle &

free alkali. - The oil obtained will be light in colour, free from soap stock & called as washed

Neutralised Oil.

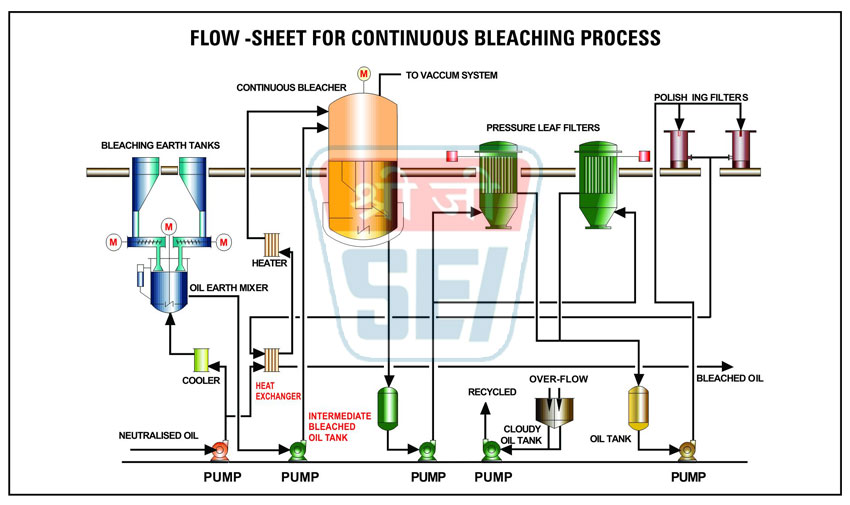

BLEACHING SECTION

- In this process excess colour from the oil is removed. The neutralized washed oil is pumped into the Bleacher vessel operating under vacuum.

- The oil is first heated to remove excess moisture and thereafter it will be treated with predetermined quantity of bleaching earth & activated carbon.

- Thereafter the oil will pass through a filter media (Pressure leaf / Filter press) to separate spent bleach earth and bleached oil.

- The oil will pass obtained after bleaching process is light in colour & appearance of oil will be clear golden in colour

DEWAXING AND WINTERISATION (FRACTIONATION)

A very simple requirement of this process is to produce Clear, Brilliant refined oil and to meet certain specifications of Cloud Point.

Sunflower and Rice Bran oil normally contain waxes compared to other oil. Therefore these oils are subjected to de-waxing process called Winterisation Plant, to remove waxes from oil and to produce sparkling good quality edible oils.

To remove the wax, the oil is first processed in Crystaliser where it is cooled by Chilled water circulation. Where the wax is converted into crystal form and there after this will be pass through the filteration process. Now, the wax is separated and the de-waxed oil is collected

SHREEJI know-how gives you an arrangement; you have been looking for since long. Our Crystalliser is Geometrically Designed for Uniform Cooling and effective Nuclei growth of particle.

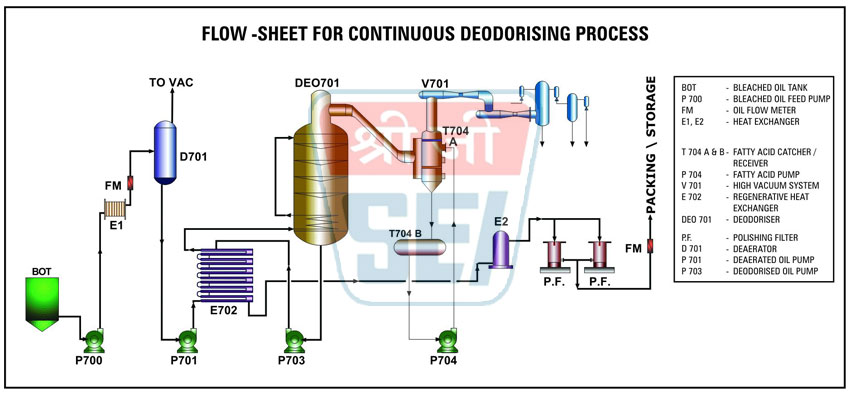

DEODORIZING SECTION

- The bleached oil is charged to deodorizer directly or through heat exchanger and is heated at high temperature and also under high vacuum in deodorizer vessel to obtain odourless clear oil.

- Once the process cycle is complete the oil obtained will be odourless & light in colour.

- After cooling it will pass through polishing filter to obtained sparkling light colour & odourless oil for packing, which will be used as edible oil.

DRY FRACTIONATION

SHREEJI’s know-how provides a Low Operating Cost Fractionation Plant which gives high olien / soft stearin yields at established control i.e. PLC (automation) for efficient working and reliability of the plant.

The separation of Stearin and Olien is continuously done on Rotary Vacuum Drum Filter and its principle is simple, whereas Crystallization process involves a perfect technique to develop and grow the particles size for easy smooth separation of Stearin and Olien.

HYDROGENATION

Hydrogenation which is also called Fat Modification is unique 3 phase process system: Solid (Nickel Catalyst), Liquid (Oil) and Gas (Hydrogen). Further a selective reaction, by bringing gas—hydrogen, liquid—oil to the solid—Ni Catalyst and this technological concept formalised an Engineering Design. SHREEJI offers Hydrogenation / Fat Modification Plant, which has several benefits